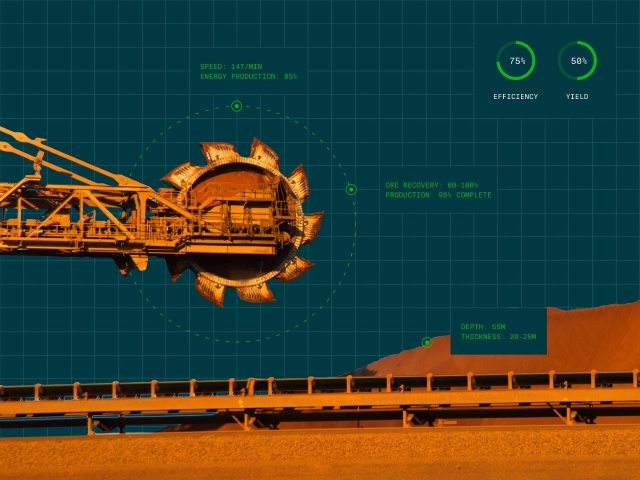

There are few environments on Earth harsher than north Western Australia. Yet it is here that some of the most sophisticated mining operations in the world take place.

Large scale automation, drones and autonomous trucks are transforming mining operations with leading mining companies deploying the latest cutting edge technology into remote locations. Rio Tinto is a pioneer in the implementation of autonomous trucks, operating a fleet of more than 193 of the vehicles, which the company claims has now shifted over one billion tonnes of material.

Not to be outdone, Fortescue Metals Group has deployed its own fleet of over 137 autonomous trucks across its iron ore operations in Western Australia with claims of increased safety, reduced fuel consumption and increased productivity.

Some things however never change, and the tyranny of distance will always be a challenge for the industry to overcome. As the rapid adoption of technology across the industry increases, so do the requirements to evolve the underpinning technology infrastructure.

When milliseconds count, on-site infrastructure is a must.

It’s for this reason that a number of leading mining companies are turning to SoftIron and HyperCloud to combat their infrastructure challenges.

SOCI compliance

The Security of Critical Infrastructure Act 2018 (SOCI) is a framework for managing critical infrastructure security in Australia.

Designed to uplift Australia’s critical infrastructure protection, successive changes to the SOCI Act put requirements on responsible entities across 11 critical sectors. Although resources are not specifically called out (energy, however, is) the desire to uplift overall cybersecurity across the sector has led many companies to review their existing infrastructure.

As Australia’s only advanced computer manufacturer, SoftIron’s solutions provide a robust basis for future SOCI compliance all but eliminating the risk of malicious state actors introducing firmware implants or so-called “backdoors” into critical information systems.

Aside from exposing Australian companies to an unacceptable business risk, the reliance on foreign-manufactured componentry has increased the risk of malicious state actors introducing covert hardware or firmware during the manufacturing process.

Tantamount to security is transparency, and as a CVE Numbering Authority (CNA), SoftIron reports any and all vulnerabilities. This ensures information technology and cybersecurity professionals can quickly identify and coordinate efforts to prioritize and address vulnerabilities and protect systems against attack, resulting in significant time and cost savings.

Edge compute capability

Mine sites produce a lot of data, all the time. 24 hours a day, 7 days a week, a plethora of platforms including IoT, drones, 3D imaging, monitoring devices, audit trail and tracking and autonomous vehicles are sending and receiving information.

Local processing of data allows for speedier decision-making and reduces dependency on transferring data to a central point for processing. Having infrastructure deployed locally that can handle a wide range of workloads, including AI and ML, are now table stakes for any modern mining operation.

Bandwidth savings

High speed or high volume data transfer from remote sites can incur significant bandwidth costs. There’s also bandwidth limitations and network congestion to think about, with both increasing the risk of data transmission errors, packet loss, and service interruptions.

With no need to be constantly connected, HyperCloud reduces usage of your expensive bandwidth, slashing communication and data transportation costs.

Reduced energy consumption

When power needs to be generated on site, and outside temperatures peak over fifty degrees Celsius (122°F) running modern IT infrastructure that generates large amounts of heat isn’t a viable proposition. SoftIron’s reductive architectural approach means that HyperCloud uses 25–35% less power than traditional IT systems.

Less power means less heat and less heat means less cooling. Which all leads to a reduction of power required on site and a reduction in the overall amount of diesel trucked to generate that power. The annual cost savings this reduced demand brings can be measured in the millions of dollars.

Zero downtime patching

System downtime leads to loss of production and revenue, particularly when those systems are essential for autonomous (and semi-autonomous) operations. Additionally, when autonomous technologies are integrated with a manned mining operation, ensuring that the underlying systems are up-to-date and performing as designed is essential for hazard control.

HyperCloud has a zero downtime patch and update process that keeps the system up and running at all times, avoiding outages caused by patch and vendor incompatibility. Zero downtime patching ensures that safety-critical systems, such as those monitoring vehicle movements or detecting hazardous conditions, remain operational at all times.

Secure-by-design

We’ve already touched on the increased regulation to address cybersecurity risks to Australia’s critical infrastructure. In addition to regulatory non-compliance, the impact of a successful system infiltration may disrupt operations and introduce safety risks. It could also result in data breaches, exposing sensitive information such as production data, employee records, or proprietary technology.

SoftIron designs and directly manufactures every hardware component in HyperCloud, reducing the supply chain risk of compromised or counterfeit components. Traditional hardware vendors outsource their manufacturing process, typically to China, with little insight into the factories where their components were produced.

SoftIron’s attention to detail is just as evident in the code that makes up HyperCloud, including regular, easy to apply software updates to maintain system integrity.

Procurement certainty

When your nearest capital city, happens to be one of the world’s most remote capitals, certainty of availability is a challenge constantly faced by the mining sector.

A comprehensive partner network, enables SoftIron to provide local spares and integration services. Domestic manufacturing means SoftIron’s supply chain is shortened and any environment can be built and delivered in a maximum of 12 weeks from start to finish.

Site-based data rooms

Traditional on-premises server rooms are time-consuming to plan and build and expensive to run and maintain, especially in remote locations with limited infrastructure and specialised personnel. It’s for this reason that much of the mining industry is turning to small “micro data centers” from vendors such as Zella DC to reduce cooling costs often overlooking the inefficiencies of the equipment deployed inside.

By adopting a combined transformation to both energy saving “micro data centers” and HyperCloud, site operators can slash their power consumption by more than 70%, requiring less cooling and importantly, a reduction in emergency battery backup capacity.

Optimized deployment and maintenance

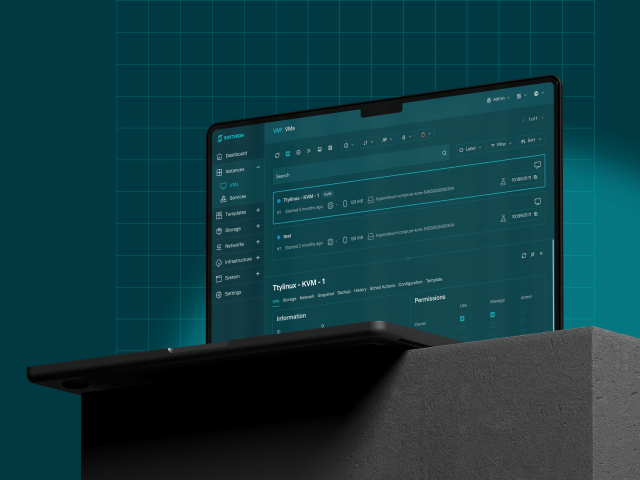

HyperCloud’s full stack interoperability and efficient design lead to optimizations that minimize maintenance and deployment resource requirements, outlined in the sections below.

Time to deploy

From unboxing to becoming fully operational, HyperCloud can be installed within four hours. It can be pre-configured off site, reducing the demand for on-site technical expertise at remote mining installations. This straightforward process also offers considerable time savings for project schedules by swiftly deploying the necessary computing infrastructure to support exploration, development, and production activities, reducing the time between planning and operational readiness.

Spares logistics and tool-less maintenance

Western Australia has stringent regulatory requirements governing workplace safety and equipment standards, particularly when it comes to the mining industry. Regular maintenance is essential for ensuring compliance with these regulations, as well as ensuring uninterrupted production. The ability to easily maintain the computing infrastructure that helps to coordinate and monitor mining operations can’t be overlooked as part of maintenance considerations.

HyperCloud offers three features that greatly streamline the maintenance process.

HyperCloud uses common components, such as the same network interface cards (NICs) and power supply units (PSUs) in both compute and storage nodes. This not only makes swapping out worn-out parts that much easier, it also reduces the number of spare parts needed to be stored on site.

HyperCloud’s tool-less design negates the need for skilled technical resources to be sent to site to replace common components. This results in fewer on-site costs and fewer requirements to transport highly skilled resources to remote sites.

Thanks to HyperCloud’s resilient architecture model, which distributes data and decision-making across multiple nodes, individual nodes can be temporarily removed from a cluster for planned maintenance without incurring downtime.

Easy expansion to complete the picture for life cycle management

If you want to get a glimpse of what the future of automation, robotics, remote sensing, and data analytics will be, then taking a look at a modern mining operation will point you in the right direction. Of course, while staying at the cutting edge pays off in terms of production and business competitiveness, all that data crunching and smart vehicle monitoring increases demand on the underlying infrastructure.

HyperCloud is just as easy to expand as it is to maintain. Rack the units, connect a few cables, and that’s it. No keyboard access required. Your new nodes will be ready for use, and available to monitor and manage in the HyperCloud Glasshouse dashboard. Life cycle management, optimized.

Automation and federation

Ensuring infrastructure remains consistent across remote sites keeps things simple when it comes to efficient operation, scalability, disaster recovery and business continuity capabilities. HyperCloud is compatible for use with infrastructure-as-Code (IaC) methodologies, enabling the use of tools like Ansible and Terraform to provide consistent remote deployments and control of workloads, minimizing the complexity of site-based setups.

Consistency is just as important for security. Consistent access controls and standardized security policies are essential for ensuring uniform protection against cyber threats and data breaches. But these policies and controls need to evolve over time, leading to divergent (and often insecure) work-arounds from site to site. Utilize federation with HyperCloud to enable IT staff to centralize security management, and further reduce management complexity across all federated sites.

To understand how a true private cloud can transform your smart mining operation, reach out to SoftIron, or one of our trusted SoftIron + Co partners today.